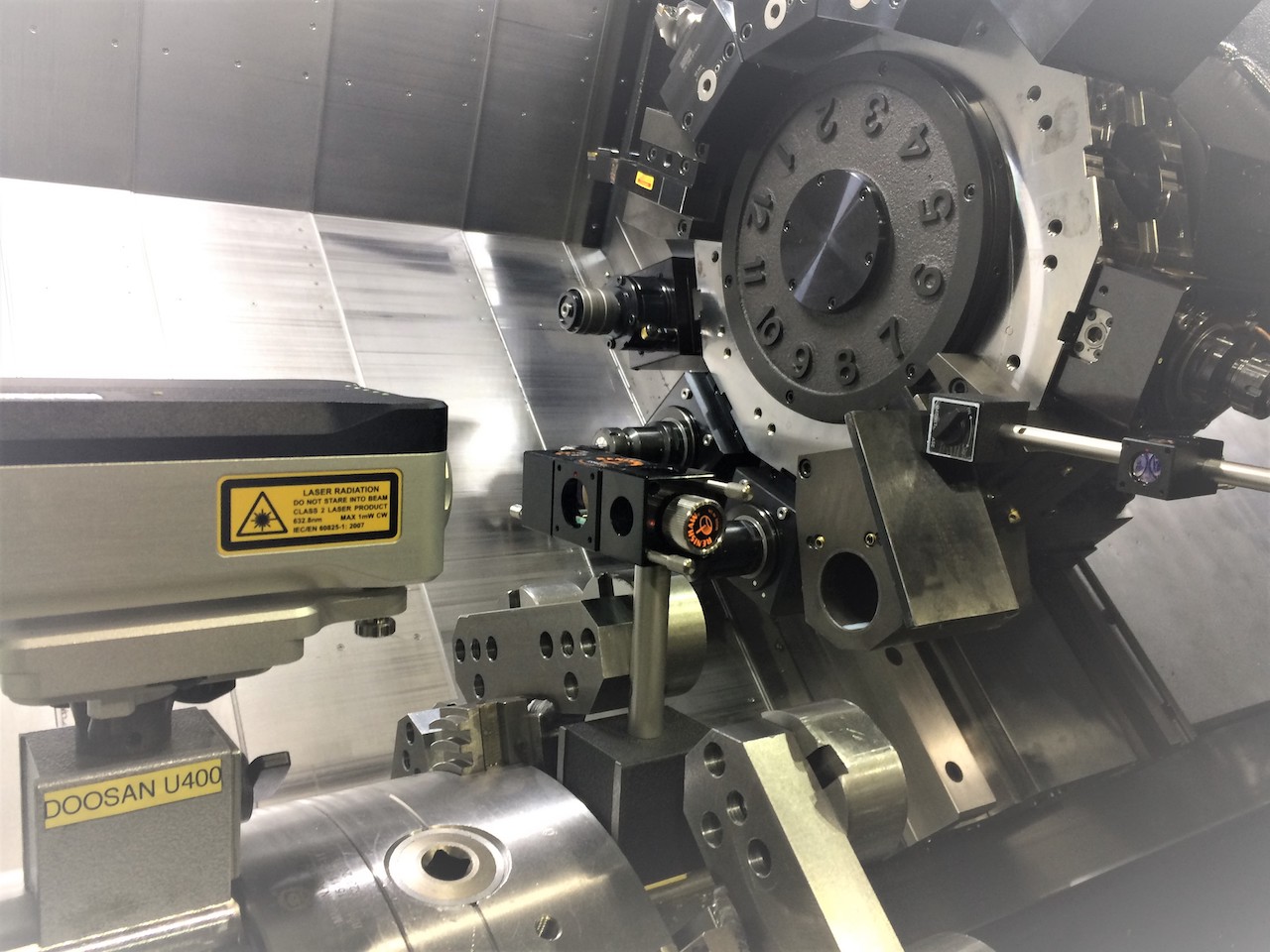

BALL BAR TEST

Using the RENISHAW QC20-W Ball Bar, we offer the simplest and fastest way to assess the main geometrical and dynamic performances of your machine tool in compliance with ISO 230-4 or ANSI/ASME B5.54.Backlash, reversal spikes, slop, straightness, squareness, roll, cyclic issues and scaling mismatches for each axis are diagnosed and machine accuracy is calculated.

This test will help you to:

- Reduce machine down time and implement fact base predictive maintenance

- Ensure accurate parts and reduce scrap

- Inspection of a second hand machine